Pasteurisation is at the heart of many Food and Drink manufacturing facilities. The purpose is to produce consistent, safe and hygienic products.

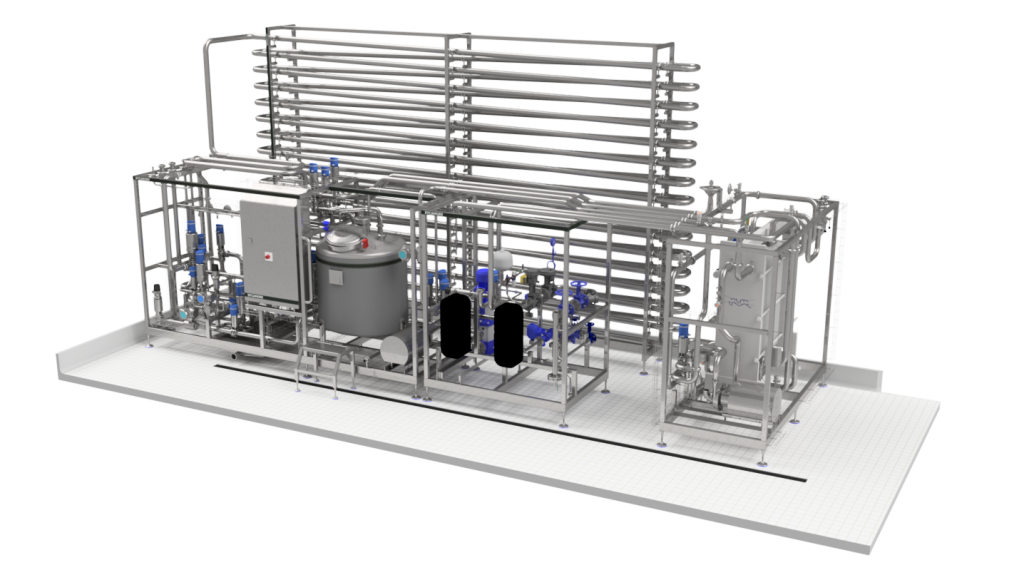

Our systems are designed to accommodate a range of plate, tubular or scraped surface heat exchangers, which are used to process a wide range of food types with differing viscosities. We acknowledge that each application has its own unique requirements, which alongside the latest codes of practice guide our designs.

When delivering your Pasteurisation system, our priority is to design the most energy-efficient solution, resulting in the lowest operational expenditure and promoting a sustainable future.

We understand what matters to you throughout the pasteurisation process. Gentle handling of every product is paramount to ensure product integrity is upheld with a hygienic design whilst minimising product wastage. To ensure no product contamination all of our pasteurisers incorporate pressure differential monitoring across the heat exchangers with the use of pressure transmitters.

Our custom designs are not limited to the plant’s process performance; we also account for future servicing and maintenance. The design of your pasteuriser will allow routine maintenance to be carried out quickly and effectively, minimising production downtime, whilst ensuring your pasteuriser is performing at its optimal level.

Lowest OPEX

Designed to maximise efficiencies – minimising steam and energy consumptions

Ergonomics

Pasteurisation systems designed with ease of maintenance in mind

Custom Designs

Tailored to suit specific requirements considering product compositions

Sustainability

Working with you when specifying pasteurisation systems to help achieve your sustainability goals

Innovations

Innovative solutions incorporating site utilities such as LTHW from CHP/Biomass enabling zero steam usage