Filter by:

- Include Dairy case studies

- Include Cheese case studies

- Include Food case studies

- Remove explicit inclusion of Beverage case studies

- Remove explicit inclusion of Plant case studies

- Remove explicit inclusion of Process Solutions case studies

- Include CIP Systems case studies

- Include Pasteurisation case studies

- Include Membrane Filtration case studies

- Remove explicit inclusion of Cheese processing case studies

-

Cream Storage and Mixproof Routing Manifold

Cream Storage and Mixproof Routing Manifold

Sycamore Process Engineering have recently delivered a Bulk Cream Storage and Mixproof Routing Manifold for a major dairy co-operative at their processing facility in Devon. This project was a complete end-to-end process solution from mechanical and process design, manufacture, installation and commissioning. The requirement for this project arose from our customer originally only having internal […]

-

Process Upgrades at Princes Cardiff Centre of Excellence

Process Upgrades at Princes Cardiff Centre of Excellence

Sycamore Process Engineering has recently delivered phase 3 of Princes Group process upgrades at their Cardiff Centre of Excellence. This project involved the relocation of equipment from their former Manchester production facility, upgrades of existing equipment as well as specification and installation of new process equipment. The initial stages of this project were led by […]

-

The North British Distillery Company Clean In Place Project

The North British Distillery Company Clean In Place Project

Sycamore Process Engineering has recently delivered a three-tank, two-channel, fully automatic Clean in Place (CIP) System for The North British Distillery Company (TNBDC) at their Edinburgh distillery. “The design of the system has enabled TNBDC to undertake segregated cleaning of equipment, reducing production downtime, offering increased reliability and safety improvements throughout the CIP cleaning system.” […]

-

Working With Hall & Woodhouse

Working With Hall & Woodhouse

Hall and Woodhouse (H&W) are a local brewery with a history dating back to when they were founded in 1777, with a rich history of brewing and supplying their much-loved beers throughout the south of England. Recently we delivered our latest project for H&W, over the years we have always seen it as important to […]

-

Three Tank Whey Protein Concentrate Export System

Three Tank Whey Protein Concentrate Export System

The team at Sycamore Process Engineering has recently completed an upgrade to a Three Tank Whey Protein Concentrate (WPC) Export System for our customer in Northern Ireland. The customer has operations across the UK and Ireland, producing a wide range of dairy products that are sold in the UK and Ireland while being exported to […]

-

New and improved desserts plant for Shrewsbury creamery

New and improved desserts plant for Shrewsbury creamery

The team at Sycamore Process Engineering has recently completed a desserts plant upgrade for one of the UK’s leading dessert manufacturers. The creamery, which makes a huge range of desserts in a variety of shapes, sizes and flavours, had three existing dessert processing plants, each with a pasteuriser at its core. Over time the heat exchangers […]

-

Sycamore Process Engineering completes multi-million pound yoghurt production facility for Yeo Valley

Sycamore Process Engineering completes multi-million pound yoghurt production facility for Yeo Valley

Sycamore Process Engineering is thrilled to have completed a new yoghurt manufacturing facility for family-owned farming and dairy company, Yeo Valley. The new facility will enable Yeo Valley to produce the brands new Super Thick Kerned Yoghurt and deliver greater levels of efficiency and consistency. Having Sycamore as one of our major partners has been […]

-

Working with Wyke Farms

Working with Wyke Farms

Sycamore has a long established working relationship with Wyke Farms, based on consistently delivering high quality solutions. Recent work has included installing all stainless steel pipework for the new Biogas Plant and the installation and commissioning of a new chiller, large enough to serve the future needs of the cheese dairy. Wyke Farms have been […]

-

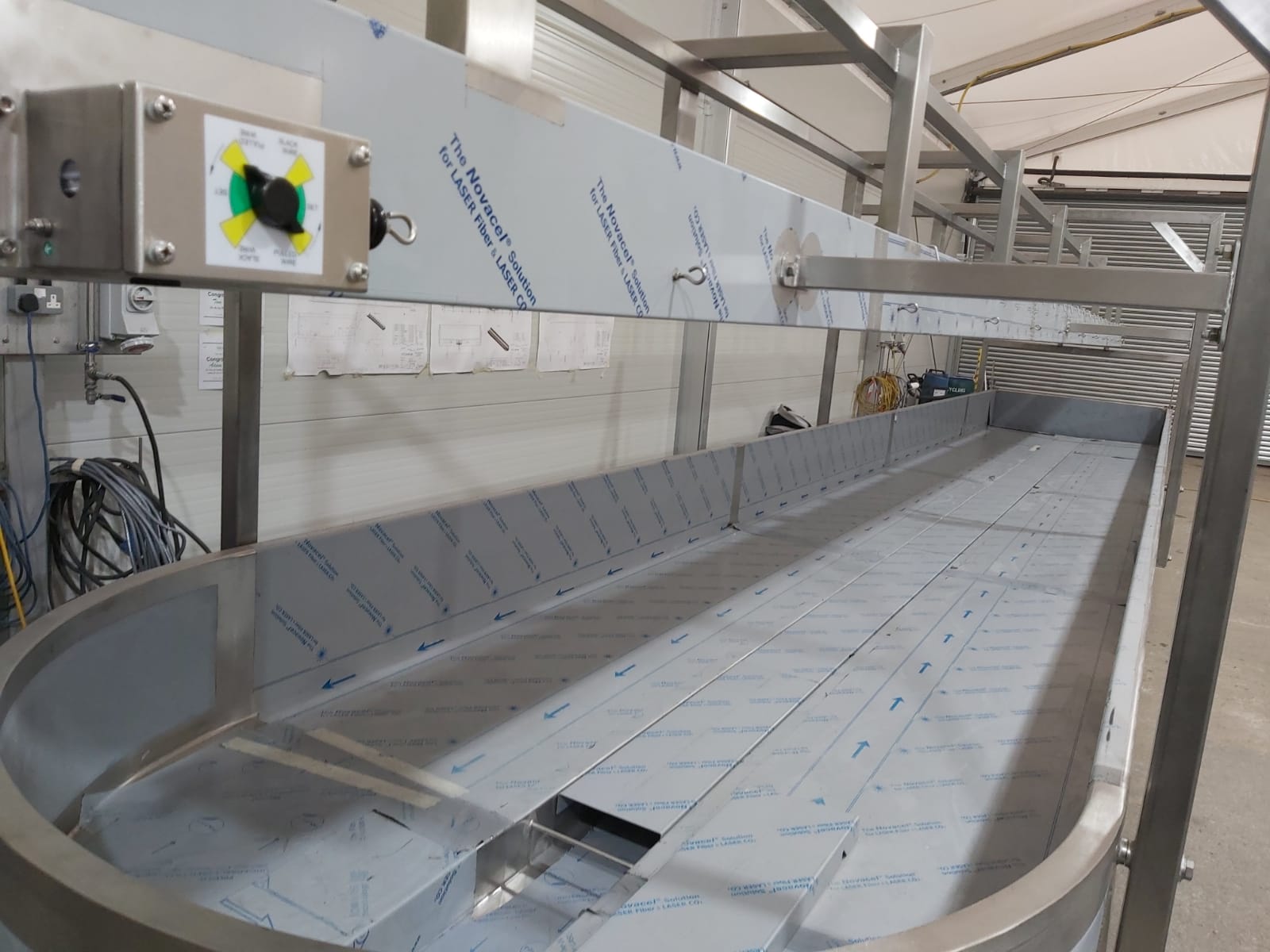

International Order of Open Curd Tables

International Order of Open Curd Tables

Sycamore Process Engineering has designed, built, and delivered several Open Curd Tables (OCTs) to effectively perform curd conditioning, whey drainage, curd salting, and mellowing for milled cheddar and stirred type cheeses. Our OCT is constantly under review to continually improve our offering, ensuring customers receive a product that exceeds their every need and expectation. Our […]

The training package delivered by Sycamore provided a good baseline knowledge to the wider Volac team but also provided a far deeper understanding to the process operators and maintenance and engineering teams. The detailed presentation and hands-on session provided a complete package of how to use and maintain our recent investment. The content was tailored to the equipment supplied but also offered an insight into real-world usage and maintenance. I would highly recommend Sycamore for the delivery of a training programme. The enthusiasm, detailed content, and flexibility were well received by the staff at Volac Whey Nutrition.