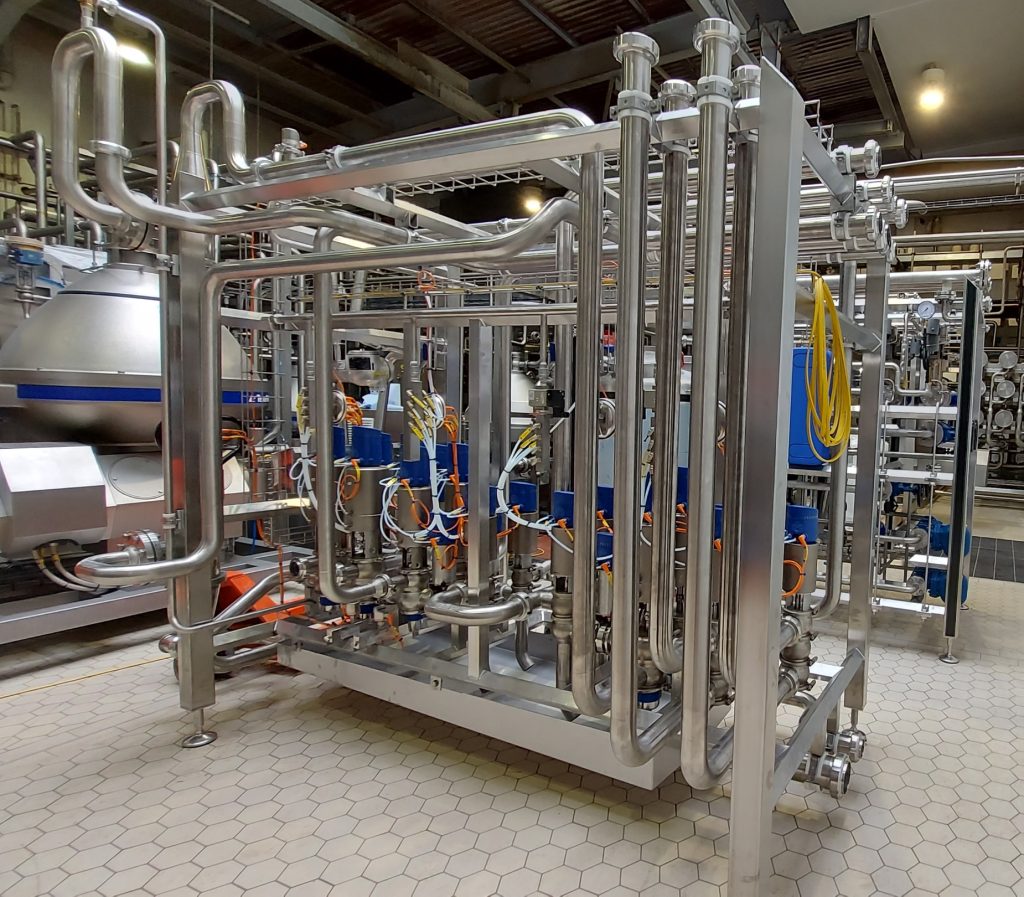

In a display of manufacturing excellence, our skilled team of Welder/Fabricators has completed the construction of this end-to-end process solution, set to transform our customer’s processing capabilities.

By adopting a modular design, this solution has been manufactured and pre-wired in our workshops to ensure a seamless onsite delivery phase with reduced risks and minimal disruption to production.

The system features pre-filtration duplex filters with auto changeover, safeguarding the membranes within the Nano Filtration plant from any potential damage from receiving any fines or fat. The membrane filtration system has been designed by our exclusive partners, Wafilin Systems, and precisely manufactured in-house alongside the other modules of this process solution.

Following its successful completion, our installation team has swiftly sprung into action, seamlessly ingressing the process vessels and modules into the customer’s production facility. Leveraging a modular approach, the installation process has been streamlined, reducing onsite time and maximising efficiency while ensuring the highest standards of safety and quality.

With the project progressing smoothly, final integration works are underway, including the routing of pipework and utilities to this new process line. This will pave the way for an imminent commissioning phase, which will see the equipment trialed and tested ensuring it operates as intended.

Read more about our end-to-end process solutions here and explore the variety of solutions we offer here.