Filter by:

- Remove explicit inclusion of Dairy case studies

- Include Cheese case studies

- Remove explicit inclusion of Food case studies

- Remove explicit inclusion of Beverage case studies

- Remove explicit inclusion of Plant case studies

- Remove explicit inclusion of Process Solutions case studies

- Include CIP Systems case studies

- Include Pasteurisation case studies

- Remove explicit inclusion of Membrane Filtration case studies

- Remove explicit inclusion of Cheese processing case studies

-

Working with Wyke Farms

Working with Wyke Farms

Sycamore has a long established working relationship with Wyke Farms, based on consistently delivering high quality solutions. Recent work has included installing all stainless steel pipework for the new Biogas Plant and the installation and commissioning of a new chiller, large enough to serve the future needs of the cheese dairy. Wyke Farms have been […]

-

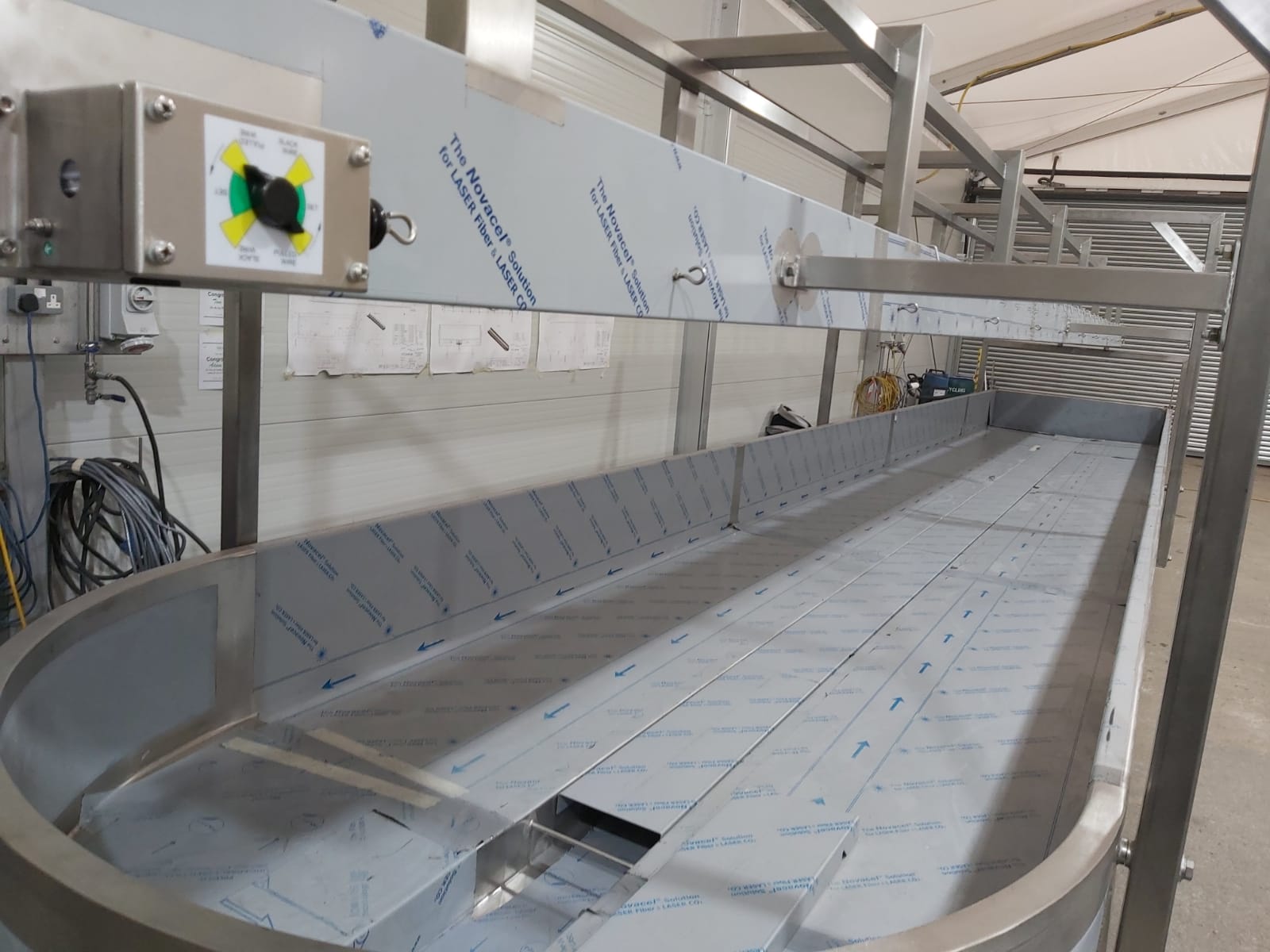

International Order of Open Curd Tables

International Order of Open Curd Tables

Sycamore Process Engineering has designed, built, and delivered several Open Curd Tables (OCTs) to effectively perform curd conditioning, whey drainage, curd salting, and mellowing for milled cheddar and stirred type cheeses. Our OCT is constantly under review to continually improve our offering, ensuring customers receive a product that exceeds their every need and expectation. Our […]

-

Heinz Telford CIP System

Heinz Telford CIP System

Another Clean in Place (CIP) project has been completed by Sycamore Process Engineering. The successful delivery of a four tank, three channel CIP system for Kraft Heinz at their production facility in Telford. As the go-to experts for CIP systems in the dairy, food, and beverage industries we have been able to provide a fully […]

-

New syrup bulk storage, tanker loading system and containerised CIP set installed at Saputo Davidstow

New syrup bulk storage, tanker loading system and containerised CIP set installed at Saputo Davidstow

Sycamore Process Engineering is pleased to have designed, manufactured, and commissioned new GOS syrup bulk storage, a tanker loading system and fully automatic, containerised CIP set for the UK cheese giant, Saputo. The projects, which took place at the Saputo creamery in Davidstow, included the Design, installation, and commissioning of a transfer line from the […]

-

Sycamore delivers new cheese vat room for Arla Foods UK, Taw Valley

Sycamore delivers new cheese vat room for Arla Foods UK, Taw Valley

Sycamore Process Engineering was delighted to be in charge of the design, installation and commissioning of a new vat cheese room at the Arla Taw Valley Creamery in Devon. The design included a hygienic manifold system to maintain high product consistency, flexibility and quality, a process which will bring significant benefits to one of the […]

-

Sycamore Process Engineering delivers three (OCT’s) Open Curd Tables for one of the UK’s leading cheese makers

Sycamore Process Engineering delivers three (OCT’s) Open Curd Tables for one of the UK’s leading cheese makers

Open Curd Tables are fantastically versatile pieces of cheese making equipment as they allow the user to produce multiple cheese types with simple adjustments to the recipe and method. Sycamore Process Engineering was delighted to be able to support one of the largest independent UK cheese makers in doing just this with the design, build […]

-

New dryer for Express Contract Drying

New dryer for Express Contract Drying

In 2015 Sycamore provided a mechanical fabrication and installation service for Express Contract Drying (ECD), the largest independent spray dryer of food flavours and colours in the UK. With seamless project management, Sycamore were a pleasure to work with. Nick BallFactory Manager Sycamore fabricated and installed many of the major items of plant and equipment […]

-

Juice pasteurising process module for Framptons

Juice pasteurising process module for Framptons

As well as working independently, Sycamore partners global process engineering companies on a regular basis, resulting in cutting edge technologies being professionally installed at competitive rates. A leading west country based beverage and liquid food processor and packager recognised the benefits of this approach and employed it on several occasions. Tetra Pak worked closely with […]

The training package delivered by Sycamore provided a good baseline knowledge to the wider Volac team but also provided a far deeper understanding to the process operators and maintenance and engineering teams. The detailed presentation and hands-on session provided a complete package of how to use and maintain our recent investment. The content was tailored to the equipment supplied but also offered an insight into real-world usage and maintenance. I would highly recommend Sycamore for the delivery of a training programme. The enthusiasm, detailed content, and flexibility were well received by the staff at Volac Whey Nutrition.